Eventuri Bmw F8X M3/M4 V2 Carbon Fiber Intake

Fitting Details

- INSTALLATION AVAILABLE

Performance Gain: 15-20hp, 18-23ft-lb

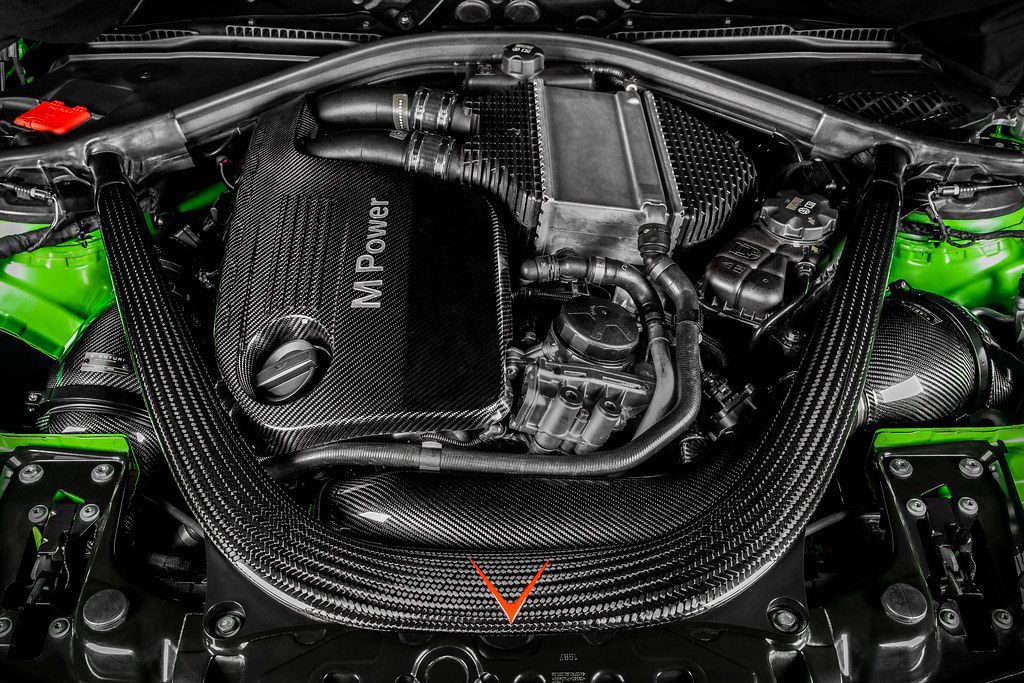

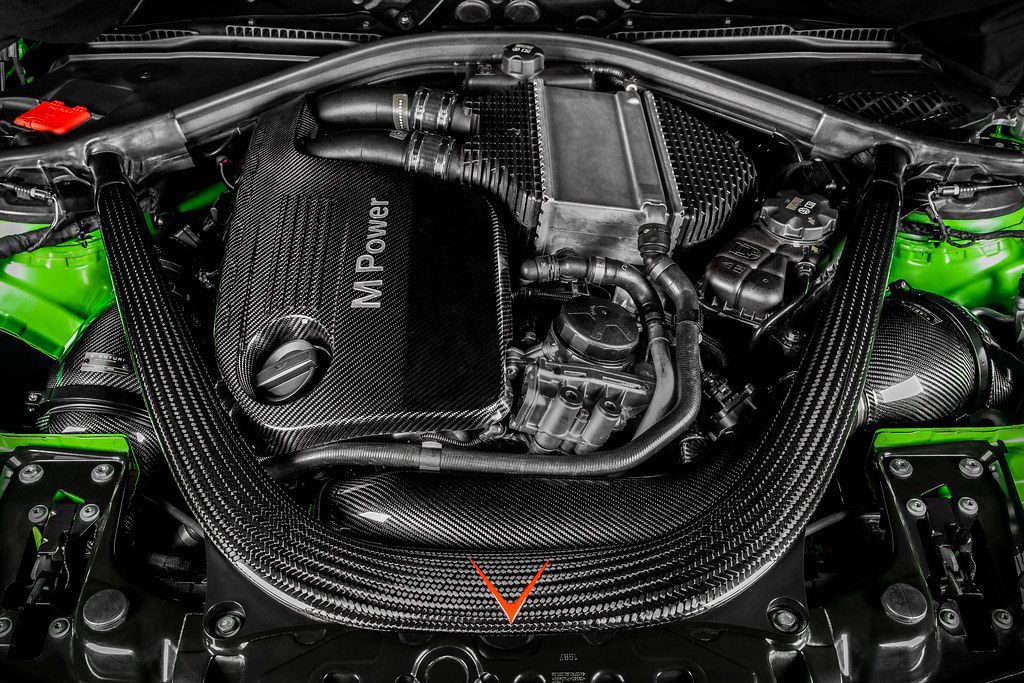

The F8X M3/M4 intake system is one of our most ambitious intake systems to date. Now in the updated V2 design, it features sealed filter housings to maintain a more steady IAT, even while stationary. The new ducts which seal the housings, coupled with our scoops ensures unrestricted airflow whilst maintaining low IATs through cold air saturation. Every detail was taken into account to ensure that we created a flagship intake to set a benchmark for this platform. From the scoops to the ducts to the intake tubes – we developed a “complete solution” to ensure a smooth inlet track with cold air saturation. With a carbon weave to match the OEM M Performance carbon – this truly is a new benchmark.

The Eventuri Difference

The F8X M3/M4 Eventuri system uses our Patent Pending Carbon fibre Housing which provides an aerodynamically efficient airflow path from the filter to the MAF tube. Not just another cone filter with a heat shield but a unique design which invokes the Venturi affect.

Product Details

Part Numbers: EVE-F8XMV2-CF-INT : BMW F8X M3/M4 V2 Full Black Carbon intake with SEALED Carbon ducts

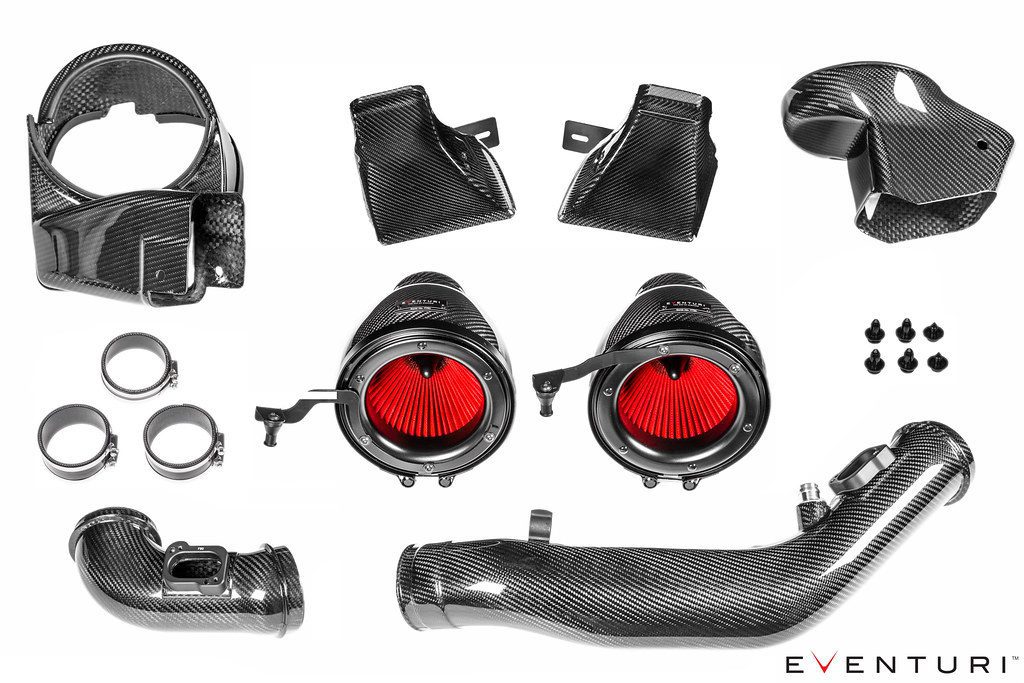

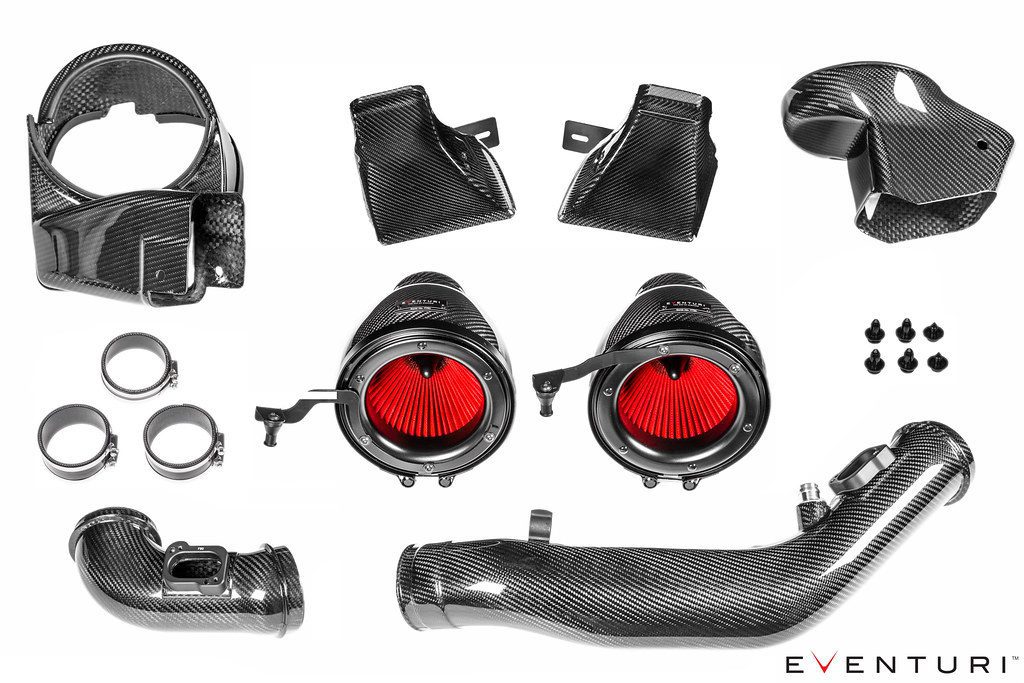

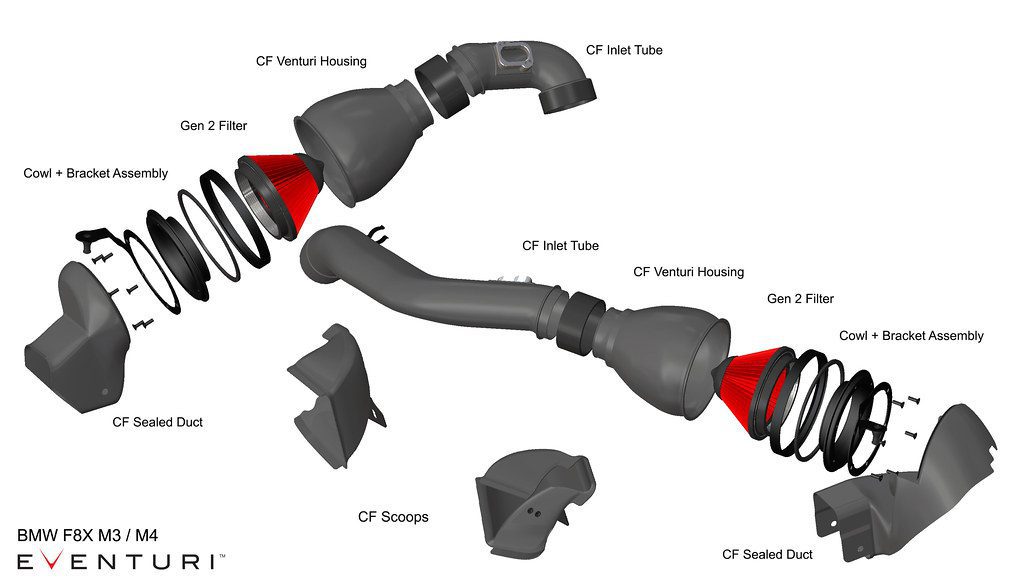

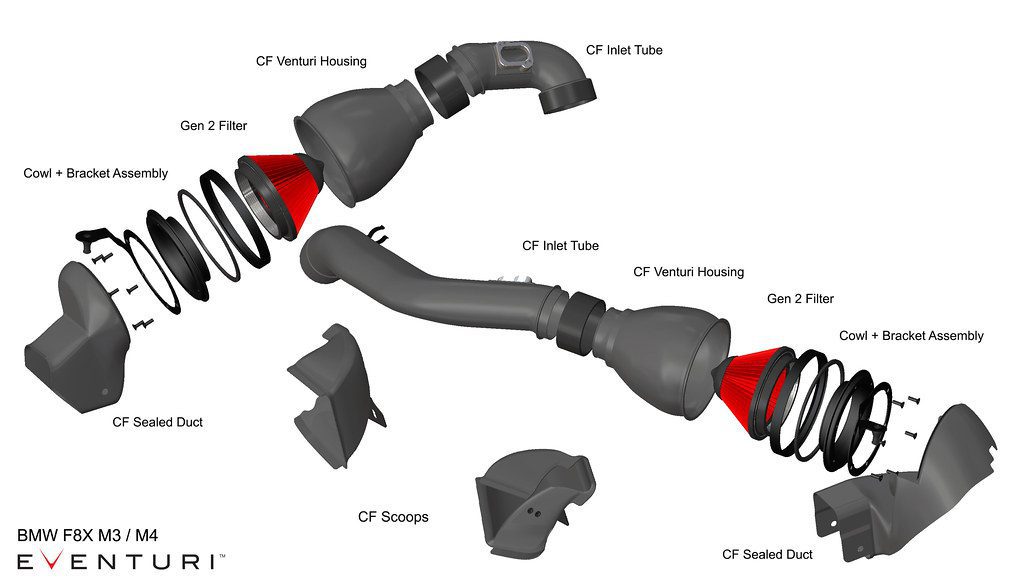

The Eventuri F8X M3/M4 intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

2 Carbon Fiber Venturi housings

2 High Flow Gen 2 Filters

2 Aluminium Cowls for smooth airflow entry

Left Side Carbon Tube with integrated MAF sensor mount

Right Side Carbon Tube with integrated MAF sensor mount

2 Carbon Fiber Sealed Intake Ducts

2 Carbon Fiber Front Scoops

Laser Cut Stainless Steel Brackets

High quality Silicon couplers with BMW specification hose clamps

CARBON FILTER HOUSINGS

The filter housings comprise of the high flow filters, aluminium cowls, V-Band clamp, laser cut brackets and the Patented carbon pods themselves. The carbon pods shroud the reverse mounted filter and smoothly shape the airflow down to the intake tubes. This geometry invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack – below is a diagram to show the comparison between our patented design and a regular intake system. Our bespoke filters aid the airflow moving through the housings and allow for an even velocity profile as the airflow exits the housings.

CARBON SEALING DUCTS

The filter housings are positioned with the openings sealed against the carbon ducts. These ducts have been designed to fit over the stock cold air ducting channels and direct ambient air into the filters. These ducts seal the openings of the filter housings and prevent heated air from entering the filters.

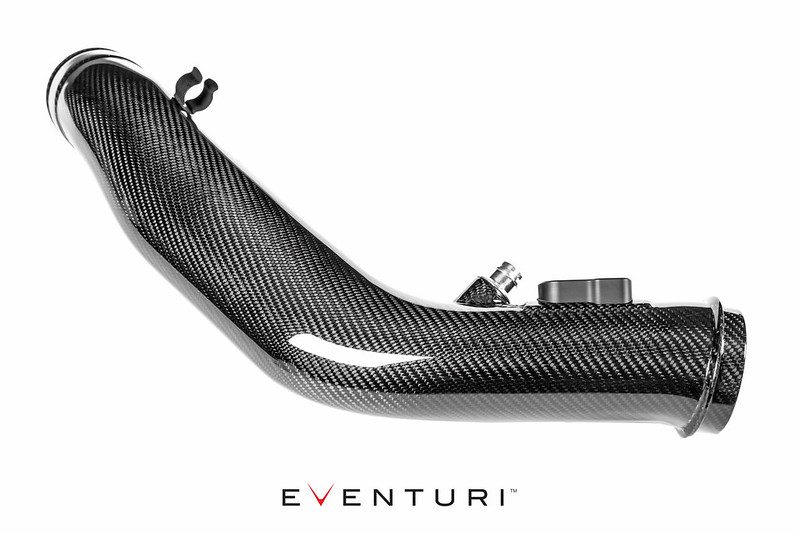

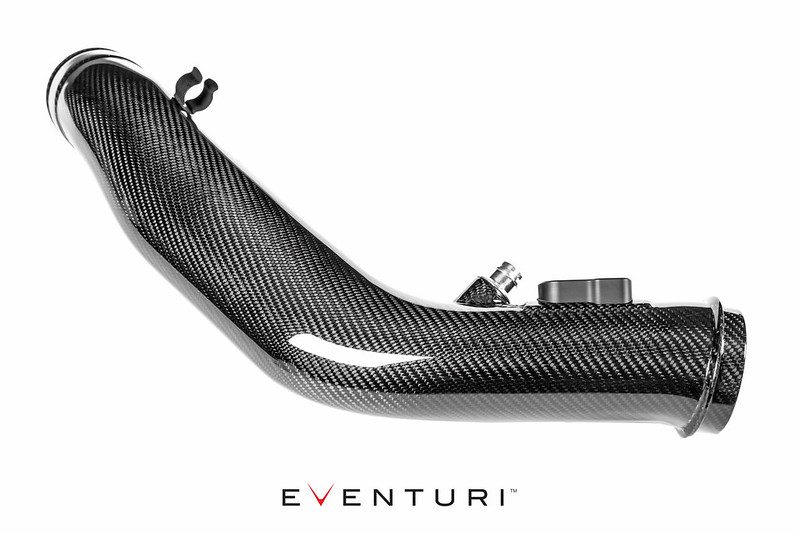

CARBON INTAKE TUBES

Our intake tubes are again crafted from 100% prepreg carbon fibre. Each tube has an integrated MAF sensor mount which is CNC machined from aluminium. The shorter left side tube smoothly transitions from the carbon housing down to the turbo inlet tube. The longer right side intake tube has to clear the fan shroud and strut brace. To do so we employed the same principle as the stock tube in changing the cross section from a circle at the turbo inlet tube to an oval for clearance over the shroud, then back to a circle at the filter housing end. We ensured these transitions were gradual so as not to disrupt airflow, furthermore we maintained the same cross sectional area in order to keep the velocity through the tube constant

CARBON AIR SCOOPS

The final components in this system are the front scoops – essential to direct ambient air to the ducts and then to the filters.

The scoops were designed for maximum efficiency in directing the incoming air to the stock duct openings. Many aftermarket scoops have a large flat area almost perpendicular to the oncoming air – not great for channeling it into the ducts as the airflow just “hits” this flat portion and creates turbulence.

The Eventuri Scoops have been designed to sit directly behind the front grills to capture as much air as possible and with a continuous curve to the duct opening to ensure this airflow is efficiently channeled.

Having an effective cold air feed to the filters is an essential part of our design. Simply having some heat shields in place is not an effective means of avoiding heated air from entering the filters unless the shields create an air tight envelope around the filters. The scoops and ducts in our system combine to provide the filter openings with ambient air and maintain low intake air temperature.

All the components come together in the engine bay to produce a genuine improvement in the driving experience as well as providing an incredible visual display of form and function in complete harmony.

£2,310.00

Out of stock

ASSETTI PRODUCTS AND SERVICES

BENEFITS OF

PPF

XPEL CERTIFIED INSTALLER

No More stone chips

Say goodbye to stone chips with XPEL PPF. The film protects the paint with a sacrificial layer which is resistant to chips and damage from debris.

ULTIMATE PROTECTION

Peace of mind that your vehicle can handle whatever the road throws at it when protected with PPF, from stone chips to bird stains PPF can protect from it all.

EASY MAINTENANCE

Keep your vehicle cleaner for longer! PPF is easier to maintain than paint thanks to it's hydrophobic properties ensuring your vehicle looks better for longer.

SELF HEALING

No more swirl marks. PPF has a self healing top coat which is resistant to light scratches and swirls. Simply park the car in the sun and watch any swirl marks fade away.