Eventuri Bmw B58 M140I M240I M340I Carbon Fiber Intake

Fitting Details

- INSTALLATION AVAILABLE

BMW B58 M140I M240I M340I CARBON INTAKE

Performance Increase : 12-15hp, 14-18ft-lb

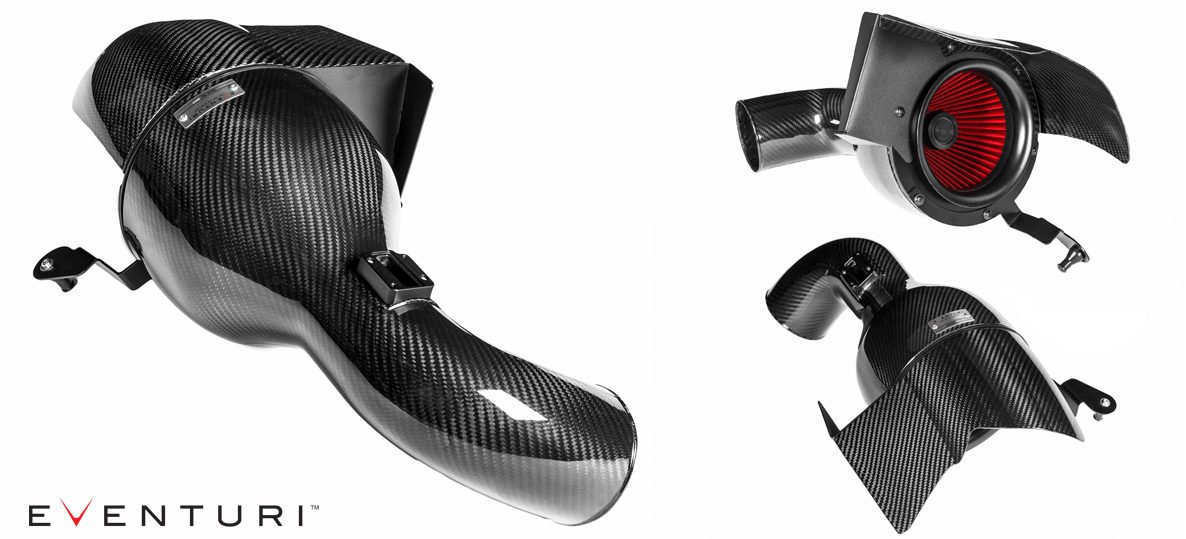

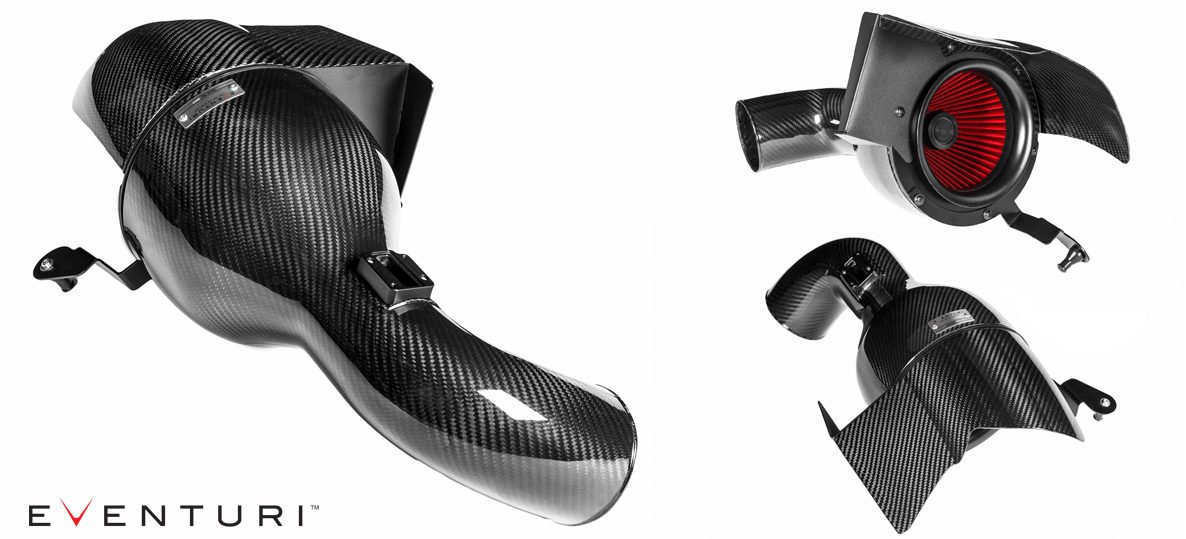

The B58 Eventuri intake system is another example of our “Complete System” principal. It demonstrates the perfect balance between allowing for unrestricted airflow with our open filter housing whilst maintaining low IAT by cold air saturation with our scoop and shield combination. Every detail has been meticulously developed from the prepreg carbon pieces to the double layer heat shields. This intake sets a new benchmark in design and craftsmanship for the B58 platform.

The Eventuri Difference

The B58 Eventuri system uses our Patent Pending Carbon fibre Housing which provides an aerodynamically efficient airflow path from the filter to the turbo. Not just another cone filter with a heat shield but a unique design which invokes the Venturi affect and maintains laminar flow conditions to reduce the drag on the turbo

Product Details

Part Numbers:

EVE-B58-CF-INT : BMW B58 F Series M140i, M240i, M340i Black Carbon intake

The Eventuri B58 intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

Prepreg Carbon Filter Housing and integrated MAF tube

High Flow Double Cone Air Filter

Aluminium Cowl for smooth airflow entry

Prepreg Carbon Scoop

Prepreg Carbon filter shroud

CNC Machined MAF Boss

Double layer main heat shield

Double layer secondary shield

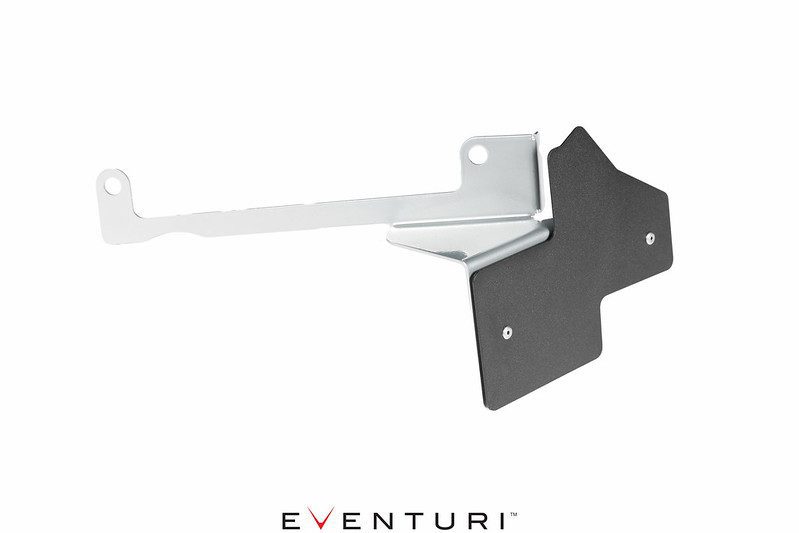

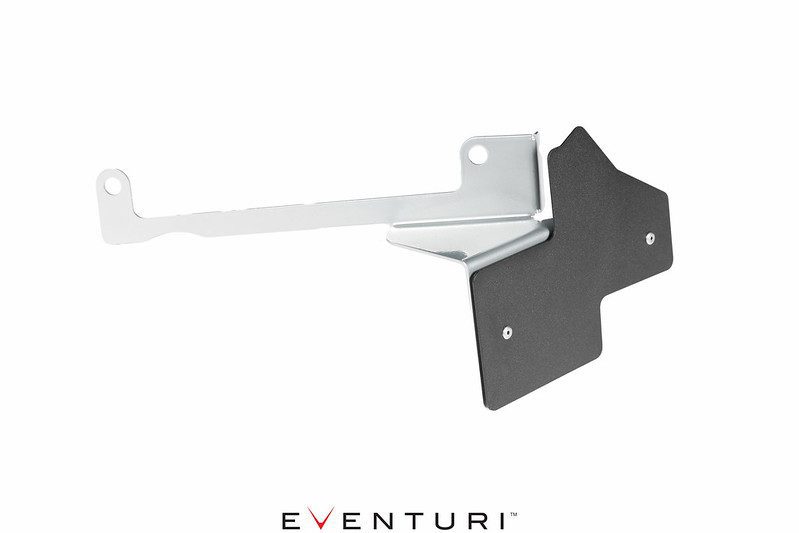

Laser Cut Mounting Brackets

Carbon Intake Housing Assembly

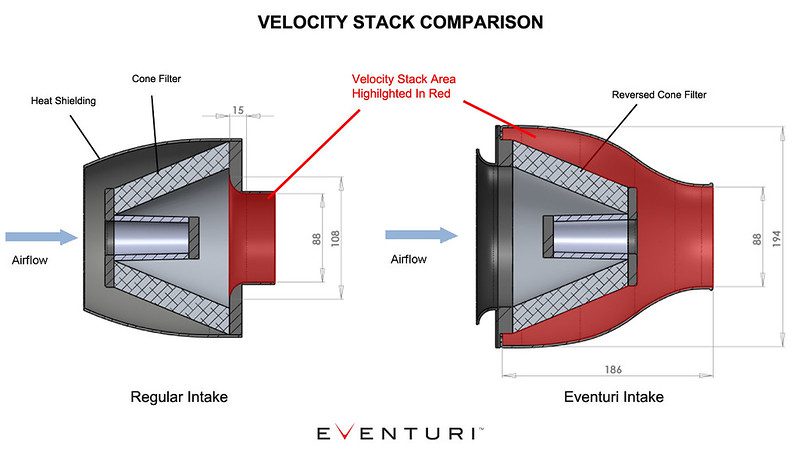

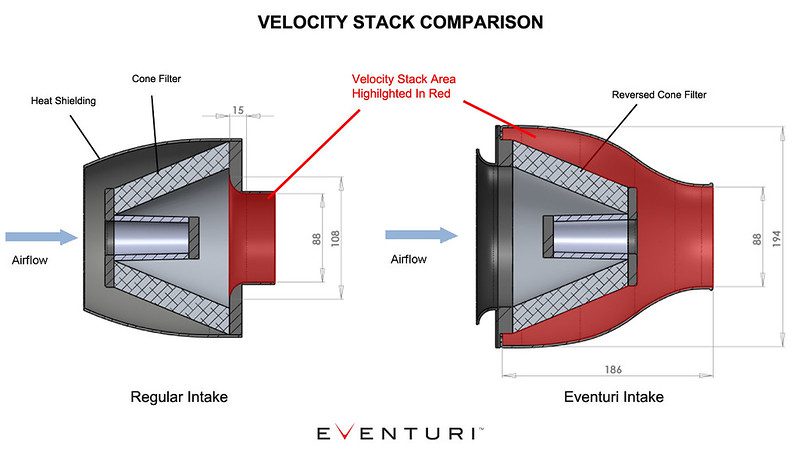

The filter housing comprises of a high flow filter, aluminium cowl, laser cut bracket, carbon heat shroud and the carbon pod itself, which extends to incorporate the MAF sensor and turbo tube. The carbon pod shrouds the reverse mounted filter and smoothly shapes the airflow down to the integrated MAF intake tube. This smooth reduction in cross sectional area invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack – below is a diagram to show the comparison between our patent pending design and a regular intake system. The carbon filter housing and the inlet tube have been integrated to be 1 continuous piece. This reduces the number of internal interfaces and allows for smoother airflow to the turbo. The diameter of the tube smoothly transitions from the required diameter at the MAF sensor end to the larger diameter of the turbo inlet.

Carbon Heat Shroud

The Carbon filter housing is mated to a carbon heat shroud and an additional aluminium shield which stop the convective heat from the exhaust manifold saturating the filter. This coupled with our comprehensive double layered heat shields combine to provide a very effective cold area around the filter opening.

The scoop was designed for maximum efficiency in directing the incoming air to the stock duct openings. Many aftermarket scoops have a large flat area almost perpendicular to the oncoming air – not great for channeling it into the ducts as the airflow just “hits” this flat portion and creates turbulence.

The Eventuri Scoops have been designed to sit directly behind the front grills to capture as much air as possible and with a continuous curve to the duct opening to ensure this airflow is efficiently channeled. The following video explains the design features behind our M2 scoop which directly apply to the B58 scoop. Having an effective cold air feed to the filter is an essential part of our design. Simply having some heat shields alone would result in elevated inlet air temperatures as the engine bay soaks with heat – especially on this engine since the manifold is directly next to the intake.

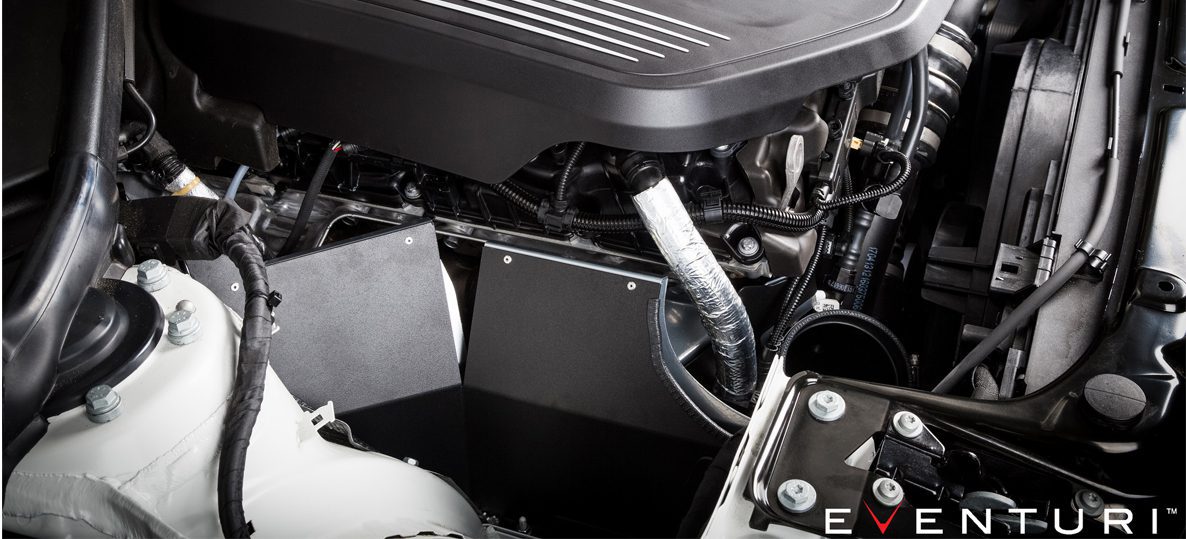

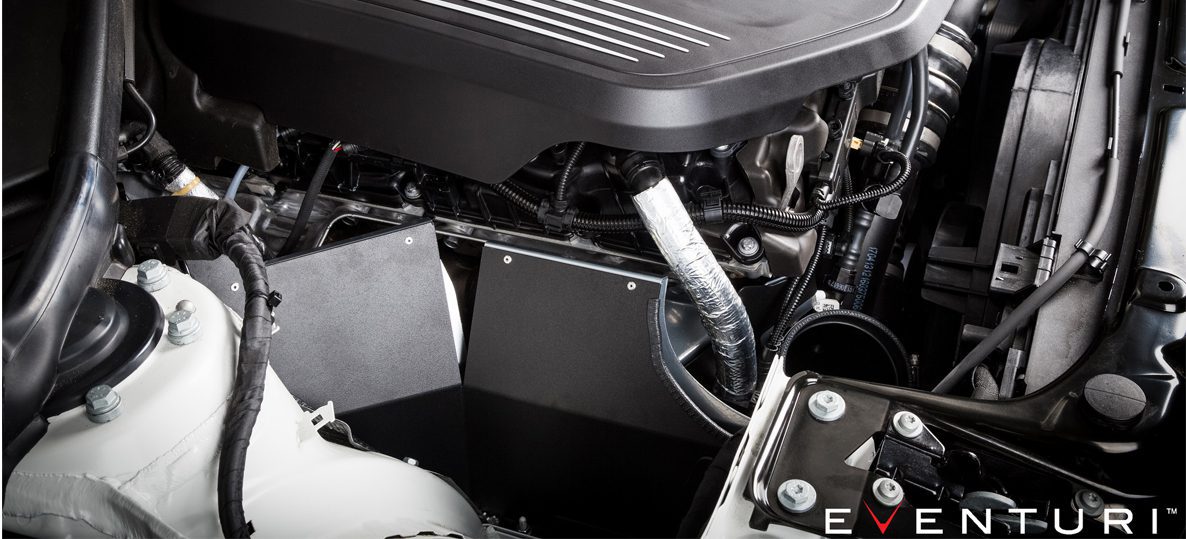

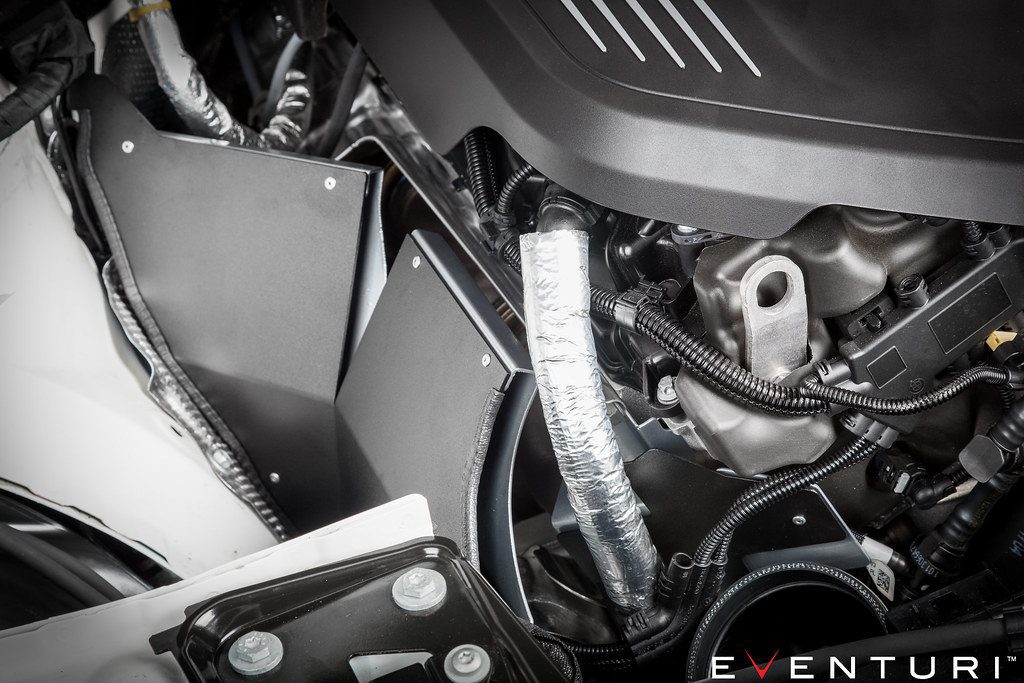

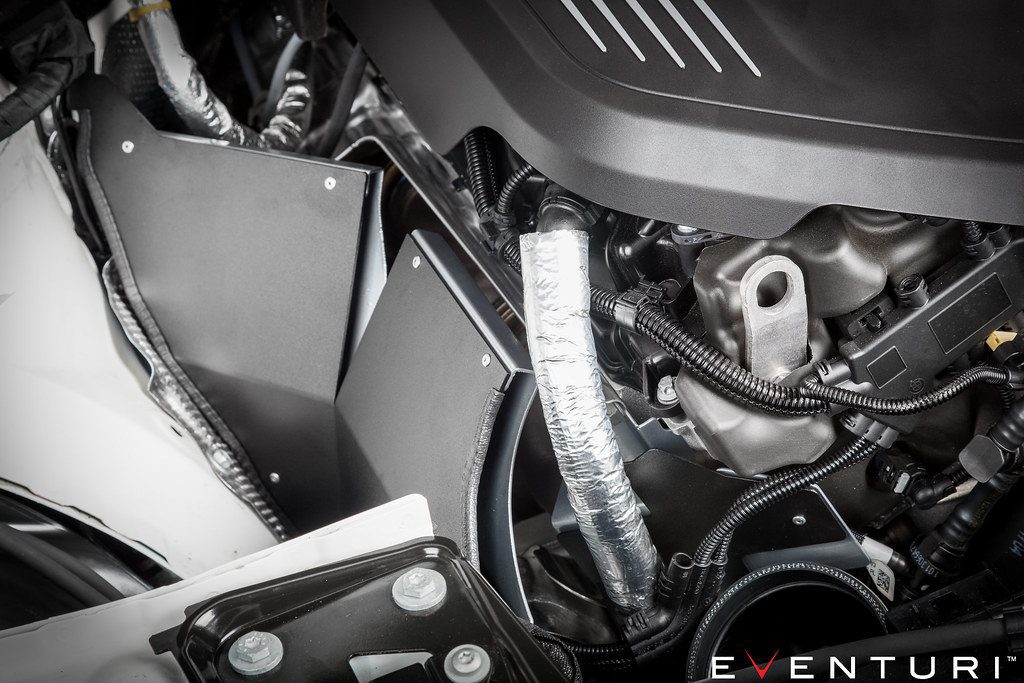

Main Heat Shield

A lot of attention was placed on the heat shielding since the intake is located next to the exhaust manifold. For this we used a double layer main shield with a silver finish on the exhaust side and black on the intake side. The silver layer reflects radiant heat from the exhaust and the black layer absorbs and radiant heat on the inlet side. The air gap between the two layers acts as an insulator to stop the conductive heat spreading to the inner layer. The secondary shield can also be seen in the above photo behind the turbo inlet pipe. During testing we found a temperature drop of over 90 degrees C across the shield which can be clearly seen in the thermal imaging video below. The effectiveness of the shield results in low inlet air temperatures whilst on the move.

The final shield mounts above the exhaust manifold and wraps around to protect the turbo inlet from direct heat saturation. Similar to the main shield – this is another double layer configuration with a silver layer on the exhaust side and a black layer on the inlet tube side.

£1,080.00

Out of stock

ASSETTI PRODUCTS AND SERVICES

BENEFITS OF

PPF

XPEL CERTIFIED INSTALLER

No More stone chips

Say goodbye to stone chips with XPEL PPF. The film protects the paint with a sacrificial layer which is resistant to chips and damage from debris.

ULTIMATE PROTECTION

Peace of mind that your vehicle can handle whatever the road throws at it when protected with PPF, from stone chips to bird stains PPF can protect from it all.

EASY MAINTENANCE

Keep your vehicle cleaner for longer! PPF is easier to maintain than paint thanks to it's hydrophobic properties ensuring your vehicle looks better for longer.

SELF HEALING

No more swirl marks. PPF has a self healing top coat which is resistant to light scratches and swirls. Simply park the car in the sun and watch any swirl marks fade away.